With the number of hazards tradesmen are faced with on the job, it’s important to have the right gear to help keep people safe on work sites. If you’re looking for a pair of boots or shoes that meet your job site’s ASTM requirements, here's what you need to know.

What does ASTM rated mean?

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. ASTM was formed in 1898 and has been around for over 120 years. They update their standards every five years.

The Occupational Safety and Health Administration (OSHA) works to ensure safe and healthy working conditions for workers by setting and enforcing standards and by, providing training, outreach, education, and assistance.

ASTM and OSHA have different functions – ASTM specifies minimum requirements for the performance of footwear to provide protection against a variety of workplace hazards that can potentially result in injury, while OSHA enforces regulations by making sure companies and workers adhere to the rules.

What is the ASTM standard for work boots?

OSHA requires protective footwear for workers at risk of injury from impacts, punctures, or electrical hazards on the work site. The footwear needs to be certified to ASTM standards to prevent injury from specific hazards.

How Do You Tell if Boots Are ASTM Approved?

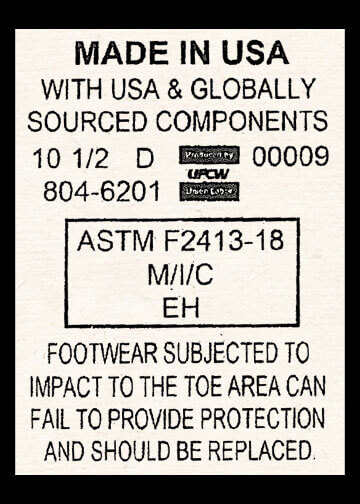

All work boots must properly label their product with ASTM standards to make it easier for consumers to select footwear that meets their workplace safety standards. You can find ASTM information on the footwear’s interior lining or inside the tongue/gusset.

All work boots must properly label their product with ASTM standards to make it easier for consumers to select footwear that meets their workplace safety standards. You can find ASTM information on the footwear’s interior lining or inside the tongue/gusset.

To decipher what the ASTM label means, you’ll need to understand the safety codes that are commonly found on work boots. These are broken down by lines. You’ll find references to boot safety features in an abbreviated format.

Do Safety Boots Expire?

Safety boots do not expire, although it’s important to keep boots in good shape or they can become compromised. For example, if your steel toe boots lose their outer layer of material and the steel beneath is exposed, it can pose a risk when dealing with electrical work since steel is conductive. The same goes for boots that have worn through soles, as they could lose their electrical insulation protection, compromise slip resistance, or lose the ability to effectively protect your feet from debris and sharp objects. Depending on how you care for your boots will also play a role in how long they maintain their integrity.

ASTM Approved Work Boots

Thorogood boots meet a range of ASTM standards, including some of the following:

- [BBP] Blood Borne Pathogens [ASTM F1671-13] - Blood-borne pathogen penetration compliant, for at least one hour when tested according to ASTM F1671-13, Standard Test Method for Resistance of Materials used in Protective Clothing.

- [MT] Metatarsal [ASTM F2413-18] - Footwear retains a 1.0-inch clearance for men’s and 0.937 inch clearance for women’s, after a nominal impact of 75 foot pounds (101.7J), i.e., a 50 lb. weight dropped, reaching 117.9 ± 2.4 inches per second velocity at impact 3.5 inches in from the toe of the footwear (3.375 inches on women’s).

- [SR] Slip-Resisting [ASTM F3445-21] - Footwear is tested for ASTM F3445-21 industry criteria for slip-resisting footwear.

- [PR] Puncture-Resisting [ASTM F2413-18] - Puncture-resisting through the sole at a force load of 1200N (270 lbf). Unique textile insole material is flexible and puncture-resisting

- Safety Toe [ASTM F2413-18] - All boots with a safety toe (either steel or composite) meet or exceed the following IMPACT and COMPRESSION testing.

- [I] IMPACT: Footwear retains a .500 inch (1/2 inch) for men’s and .468 inch (15/32 inch) for women’s or greater clearance after a nominal impact of 75 foot-pounds (101.7J), i.e., a 50 pound weight dropped, reaching 117.9 ± 2.4 inches per second velocity at impact.

- [C] COMPRESSION: Footwear retains a .500 inch (1/2 inch) for men’s and .468 inch (15/32 inch) for women’s or greater clearance after a compression force of 2500 lbs. (11,121 N).

- [EH] Electrical Hazard [ASTM F2413 or F2892-18] - Constructed or manufactured with electric shock-resisting soles and heels capable of withstanding an application of 18,000 volts (root mean square (RMS) value) at 60 Hz for 1 minute, with no current flow or current leakage in excess of 1.0 milliamperes under dry conditions.

OSHA foot protection standards requires footwear be certified impact and compression resistant when tested to ASTM standards, have non-skid soles, and built-in toe caps. The OSHA standards also require puncture-resistance and slip-resistance in footwear for construction workers.

Are Steel or Composite Toe Boots OSHA Approved?

While OSHA does not test, approve, certify, or endorse any product, performance standards are determined by ASTM. Thorogood footwear is tested to these standards. Be sure to check with your employer for any specific job requirements for PPE.

Looking for the right ASTM boots? Reach out to our customer service team with any questions and be sure to check with your employer for any specific requirements they may have.