When you’re shopping for durable, quality boots, you need to be able to identify quality constructed footwear that you can depend on. High-quality leather grade, strong soles, and Goodyear welt construction are all important components to choosing a boot that’ll stand up to hard work and harsh weather.

What is Goodyear Welt Construction?

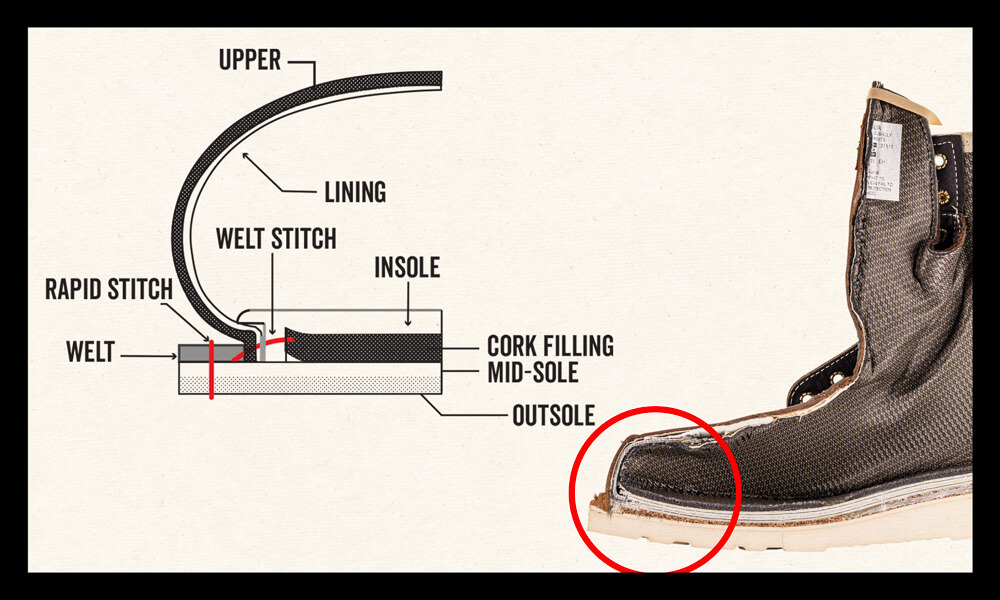

A Goodyear welt is used to attach the upper part of a boot to the sole. The welt can be leather, plastic (PVC) and/or rubber. First, the upper is sewn to the welt, and then the welt gets sewn to the sole.

Storm welt construction, which is the type of welt that Thorogood uses, is similar to that of a Goodyear constructed boot, but wider. The extra width allows the welt to be bent upwards, creating a seal around the junction between the upper and the mid-sole. Aptly named, the Storm welt is considered to offer greater moisture protection than a Goodyear welt.

Although Goodyear welt construction is more difficult than say, a Blake stitch, Thorogood work boots are constructed with this method to help improve longevity and comfort, and to create a stronger seal against moisture.

Another common way of making footwear is with cement construction, also known as gluing the upper leather to the outsole. Most sneakers and basic boots are made with this method since it’s quick and effective, but it doesn’t hold up in rugged conditions as well. When you’re looking for a boot that stands the test of time, you need welted construction.

The History of Goodyear Welts

Welted construction used to be done entirely by hand, making it too expensive for the general population, but in the 1860s, everything changed when Charles Goodyear started working on a machine that could speed up the process. By the mid-20th century, the machine had gained popularity and became the new standard in footwear production. Unfortunately, shortly later it was replaced by a cheaper alternative - cement construction, causing Goodyear welt construction to become less common amongst the working class.

Benefits of a Goodyear Welt

Here’s why a Goodyear welt is synonymous with quality footwear:

- It makes it possible to resole boots multiple times instead of having to replace them.

- It improves water resistance by minimizing water penetration to the insole.

- Goodyear welts aren’t restrictive to a certain material sole. Don’t like your work boot soles? Upgrade to Vibram® or slip-resistant soles.

- Higher quality and stronger construction make Goodyear welts more durable.

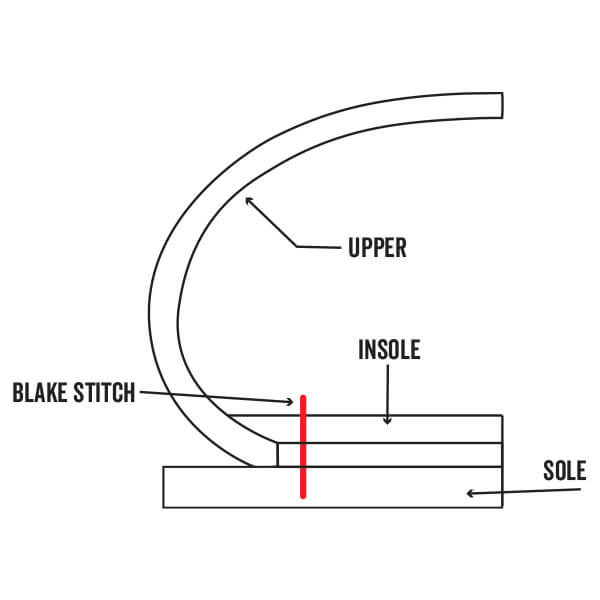

Blake Stitch vs Goodyear Welt

A Blake stitch doesn’t have the strip of material that is sewn to the upper, it directly stitches the insole to the outsole. Since it has one less layer it results in a more flexible boot. Similar to the Goodyear welt, the Blake stitch is done by machine since it requires stitching on the inside as well. While it is a less complicated form of boot construction, it makes resoling more difficult, and it doesn’t provide as much water resistance as a Goodyear welt.

When you’re looking for a strong pair of work boots, a Goodyear welt will provide the performance you need. Thorogood strives to source quality materials and focuses 100% on creating the best construction, which is made possible, in part, by the excellent team at Weinbrenner’s new manufacturing facility.