TESTING BOOTS FOR SAFETY

Thorogood takes pride in building job-fitted work boots that stand up to tough workplaces. Workplace safety hinges on being able to withstand some pretty extreme conditions. But when a worker is looking at steel toe work boots, for example, how do they know a piece of footwear is up to the rigors of the job? That’s where ASTM International comes in.

Formerly known as the American Society for Testing and Materials, ASTM International was founded in 1898 by a group of engineers worried about shoddy standards in the American railroad industry. Today, ASTM International develops global standards for everything from children’s toys to jet fuel. In order to qualify, products have to meet specific standards, tested in a lab using specialized equipment.

For footwear, these standards ensure a number of things you look for in the best work boots. You can find ASTM information on the footwear’s interior lining or inside the tongue/gusset.

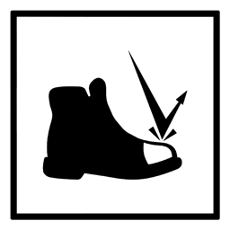

RATING SAFETY TOE SHOES & BOOTS

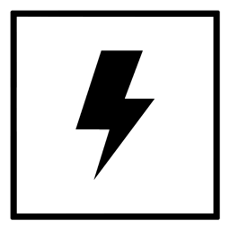

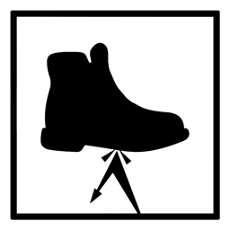

When testing footwear with protective toe caps like steel toe boots, the ASTM F2413 standard uses special equipment to test impact, compression, puncture, and electrical hazard (EH) resistance. For impact resistance, a 50 lb. weight is dropped on the toe, reaching a specific speed at impact. The toe must retain a 1/2-inch or greater clearance for men’s work boots through the impact. To meet compression standards, the boot must retain the same amount of clearance under 2500 lb. of compressive force. Puncture standards require the boot’s sole to withstand 270 lb. of force and show no cracks after 1.5 million flexes. For footwear equipped with metatarsal protection, it needs to retain an inch of clearance under 50 lb. of weight impacting 3.5 inches up from the toe. And to meet EH standards, the boot has to be constructed with shock-resisting soles and heels capable of withstanding 18,000 volts of electricity at 60 Hz for a full minute, with no current leakage under dry conditions.

By testing all kinds of footwear under the same lab conditions, ASTM can ensure that all certified footwear hits those same specifications. And as has been pointed out before, composite toe boots are every bit as protective as steel toe boots, meeting the same rigorous standards for certification.

RATING SOFT TOE BOOTS

ASTM F2892 covers safety standards like EH while omitting the impact and compression testing used in safety toe boots. And for protective work boots of all types, slip-resistance standards are established by F3445, certifying the boot’s ability to stay put under standardized testing conditions on surfaces including (but not limited to) block pavers, turf, gravel, and surfaces contaminated with liquid water, ice, oil, and grease. The boot is placed on an incline of up to 20° and subjected to lateral forces of up to 182 lb., and must not slip more than half a meter/second.

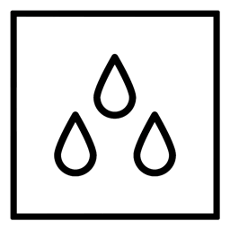

KEEPING BLOOD-BORNE PATHOGENS (BBP) OUT

One more common certification you’ll see applied to Thorogood boots is ASTM F1671, which measures footwear’s ability to resist penetration by liquids. This is particularly important for first-responder, EMS, and police boots. To pass the test, footwear must resist penetration by viruses for at least one hour in the lab. This ensures that blood or infected liquids that come into contact with the footwear can’t get in.

THE TAKE-AWAY

When these symbols, or terms like “EH-resistant” are associated with Thorogood work boots, it’s more than just a claim. Making informed decisions about the workplace footwear is crucial, and ASTM testing ensures workers are getting the right protection for the job. You can strap those boots on and go to work with the knowledge that your footwear has been thoroughly tested.